Flush toilet

"water closet" redirects here. For rooms labelled "W.C.", see public toilet.

A flush toilet is a toilet that disposes of human waste by using water to flush it through a drainpipe to another location. Flushing mechanisms are found more often on western toilets (used in the sitting position), but many squat toilets also are made for automated flushing.[1] Modern toilets incorporate an "S", "U", "J", or "P" shaped bend that causes the water in the toilet bowl to collect and act as a seal against sewer gases. Since flush toilets are typically not designed to handle waste on site, their drain pipes must be connected to waste conveyance and waste treatment systems. A flush toilet may be euphemistically called a lavatory, a bog (UK), a pot (USA), a loo, a john, a water closet (abbreviated "W.C."), or simply "toilet".

Etymology[edit]

The term "water-closet" was an early term for an interior or exterior room with a flushing toilet in contrast with an earth closet usually outdoors and requiring periodic emptying as "night soil". Originally, the term "wash-down closet" was used.[2] The term "water-closet" was coined in England around 1870. It did not reach the United States until the 1880s. Around this time, only luxury hotels and wealthy people had indoor private bathrooms. By 1890 fears in the US were arising from the theory of disease about carelessly disposed human waste being contaminated and infectious.[3] Originally, the term "bath-room" referred only to the room where the bathtub was located, which was usually a separate room, but this connotation has changed in common North American usage. In the UK, the terms "bathroom" and "toilet" are used to indicate discrete functions, even though bathrooms in modern homes often include toilets. The term "water closet" was probably adapted because in the late 19th century, with the advent of indoor plumbing, a toilet displaced an early clothes closet, closets being shaped to easily accommodate the spatial needs of a commode.[citation needed] Early indoor toilets had in fact been known as garderobes because they actually were used to store clothes, as the smell of ammonia was found to deter fleas and moths. The term "water closet" is still used today in some places, but it often refers to a room that has both a toilet and other plumbing fixtures such as a sink or a bathtub. Plumbing manufacturers often use the term "water-closet" to differentiate toilets from urinals. American plumbing codes still refer to a toilet as a "Water Closet" or a "WC". Many South American countries refer to a toilet as a "water" or "WC". The Royal Spanish Academy Dictionary accepts "váter" as a name for a toilet or bathroom, which is derived from the British term "water-closet". In French the expression "aller aux waters" ("to go to the waters") has now become obsolete, but it also derives from "water closet". "WC" is still used in the French language, although not as common as the term "toilet", and pronounced as "VC", a shortened version of "double V C". In Germany the expression "Klo" (first syllable of "closet") is still used, though the term is colloquial and not welcome in polite conversation. In Dutch and Swiss German, usage of the term "wc" is very common.Water closet[edit]

History[edit]

Further information: History of water supply and sanitation

As with many inventions, the flush toilet was the result of a long development. Therefore, instead of a single name and date, there follows a list of significant contributions to the history of the device.

- circa 31st century BC: Britain's oldest neolithic village, Skara Brae, Orkney, used neolithic hydraulic technology.[4] The village's design used a river and connecting drainage system to wash waste away.

- circa 26th century BC: Flush toilets were first used in the Indus Valley Civilization. The cities of Harappa and Mohenjo-daro had a flush toilet in almost every house, attached to a sophisticated sewage system.[5] See also Hydraulic engineering of the Indus Valley Civilization.

- circa 18th century BC: Flush toilet constructed at Knossos on Minoan Crete[6]

- circa 15th century BC: Flush toilets used in the Minoan city of Akrotiri.[7]

- 9th century BC: Flush toilets on Bahrain Island.[8]

- 1st to 5th centuries AD: Flush toilets were used throughout the Roman Empire. Some examples include those at Vindolanda on Hadrian's Wall in Britain. With the fall of the Roman Empire, the technology was lost in the West.[citation needed]

- 1206: The Arab or Kurdish inventor Al-Jazari invented a hand washing device incorporating the flush mechanism now used in modern flush toilets. His device features a mechanism for filling the basin with water. When the user pulls the lever, the water drains and the mechanism refills the basin.[9][not in citation given (See discussion.)]

- 1596: Sir John Harington (1561–1612) published A New Discourse of a Stale Subject, Called the Metamorphosis of Ajax, describing a forerunner to the modern flush toilet installed at his house at Kelston.[10] The design had a flush valve to let water out of the tank, and a wash-down design to empty the bowl. He installed one for his godmother Queen Elizabeth I at Richmond Palace, although she refused to use it because it made too much noise.[citation needed] The Ajax was not taken up on a wide scale in England, but was adopted in France under the name Angrez.[citation needed]

- 1738: A valve-type flush toilet was invented by J. F. Brondel.

- 1775: Alexander Cummings invented the S-trap (British patent no. 814?), still in use today, which uses standing water to seal the outlet of the bowl, preventing the escape of foul air from the sewer. His design had a sliding valve in the bowl outlet above the trap.

- 1777: Samuel Prosser invented and patented the 'plunger closet'.

- 1778: Joseph Bramah invented a hinged valve or 'crank valve' that sealed the bottom of the bowl, and a float valve system for the flush tank. His design was used mainly on boats.

- 1851: The first popularized public water closets were exhibited at The Crystal Palace and these became the first public toilets. They had attendants dressed in white and customers were charged a penny for use. This is supposedly the origin of the phrase "To spend a penny" which did not appear in print until the 1940s.

- 1852: George Jennings invented a wash-out design with a shallow pan emptying into an S-trap.

- 1857: The first American patent for a toilet, the 'plunger closet', was granted.

- 1858: The first flush toilets on the European continent may have been the three "waterclosets" installed in the new town house of banker Nicolay August Andresen on 6 Kirkegaten inChristiania, insured in January 1859. The toilets were probably imported from Britain, as they were referred to by the English term "waterclosets" in the insurance ledger.

- 1859: By the end of the 1850s building codes suggest most new middle-class homes in British cities were equipped with a water closet.

- 1860: Another early watercloset on the European continent was also imported from Britain. It was installed in the rooms of Queen Victoria in Ehrenburg Palace (Coburg, Germany); she was the only one who was allowed to use it.

- 1880s: Thomas Crapper's plumbing company built flush toilets of Giblin's design. Although not the original inventor, Crapper popularized the siphon system for emptying the tank, replacing the earlier floating valve system which was prone to leaks. Some of Crapper's designs were made by Thomas Twyford. The similarity between Crapper's name and the much older word crap is a coincidence.

- 1885: The first modern pedestal 'flush-down' toilet was demonstrated by Frederick Humpherson of the Beaufort Works, Chelsea, England.[11]

- 1885: Thomas Twyford built the first one-piece ceramic toilet using the flush-out siphon design by J. G. Jennings.

- 1898: Albert Giblin received British patent 4990 for the "Silent Valveless Water Waste Preventer", a siphon discharge system.[citation needed][12]

- 1906: William Elvis Sloan invented the Flushometer, which used pressurized water directly from the supply line for faster recycle time between flushes. The Flushometer is still in use today in public restrooms worldwide.

- 1907: Thomas MacAvity Stewart of Saint John, New Brunswick patented the vortex-flushing toilet bowl, which creates a self-cleansing effect.[13]

- 1911: Philip Haas of Dayton, Ohio, developed the flush rim toilet, which depended on multiple jets of water from a ring with downward-pointing perforations to thoroughly wash every portion of the bowl, as described in US Patent Number 1,107,515.

- 1924-1927: Philip Haas of Dayton, Ohio, designed and improved a water closet flushing and recycling mechanism similar to those in use today, incorporated in US Patents 1,576,600, 1,601,210, 1,605,939, 1,623,109, 1,629,914, 1,638,395, 1,639,997, 1,660,922.

- 1980: Bruce Thompson, working for Caroma in Australia, developed the Duoset cistern with two buttons and two flush volumes as a water-saving measure. Modern versions of the Duoset are now available worldwide, and save the average household 67% of their normal water usage.[14]

Flushing mechanism[edit]

The flushing mechanism provides a large flow of water into the bowl (which is described later in this article). The mechanism usually incorporates one or more parts of the following designs:

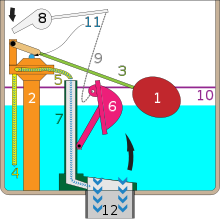

Tank fill valve[edit]

Tank fill valves are found in all tank-style toilets. The valves are of two main designs: the side-float design and the concentric-float design. The side-float design has existed for over a hundred years. The concentric-design has only existed since 1957, but is gradually becoming more popular than the side-float design, and Fluidmaster, founded in the United States by inventor Adolf Schoepe, makes them.

The side-float design uses a float on the end of a lever to control the fill valve. The float is usually shaped like a ball, so the mechanism is called a ball-valve or a ballcock. Cock is a term for valve; see, for example, stopcock. The float was originally made from copper sheet, but it is now usually plastic. The float is located to one side of the main valve tower at the end of a rod or arm. As the side-float rises, so does the side-float-arm. The arm connects to the fill valve that blocks the water flow into the toilet tank, and thus maintains a constant level in the tank.

The newer concentric-float fill valve consists of a tower which is encircled by a plastic float assembly. Operation is otherwise the same as a side-float fill valve, even though the float position is somewhat different. By virtue of its more compact layout, interference between the float and other obstacles (tank insulation, flush valve, and so on) is greatly reduced, thus increasing reliability. The concentric-float fill valve is also designed to signal to users automatically when there is a leak in the tank, by making much more noise when a leak is present than the older style side-float fill valve, which tends to be nearly silent when a slow leak is present.

Tank style with flapper-flush valve[edit]

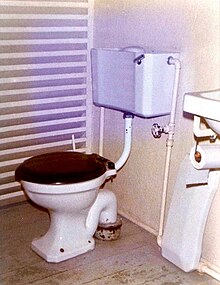

In a tank-based system, the storage tank (or cistern) collects between 6 and 17 liters of water over a period of time. This system is suitable for locations plumbed with 1/2" (15 mm) or 3/8" (10 mm) water pipes. These small diameter pipes cannot supply water quickly enough to flush the toilet; the tank is needed to supply a large volume of water in a short time. The storage tank is kept full by a tank fill-valve. The storage tank is usually mounted directly upon the bowl, although some tanks are mounted on the wall a few feet above the bowl in an attempt to increase the flush water pressure as it enters the bowl. Tanks near the ceiling are flushed by means of a dangling pull chain, often with a large ornate handle, connected to a flush lever on the cistern itself. "Pulling the chain" remains a British euphemism for flushing the toilet, although this type of tank or cistern is becoming rare. A similar German expression is Wasser ziehen ("to pull water").

In tanks using a flapper-flush valve, the outlet at the bottom of the tank is covered by a buoyant (plastic or rubber) cover, or flapper, which is held in place against a fitting (the flush valve seat) by water pressure. To flush the toilet, the user pushes a lever, which lifts the flush valve from the valve seat. The valve then floats clear of the seat, allowing the tank to empty quickly into the bowl. As the water level drops, the floating flush valve descends back to the bottom of the tank and covers the outlet pipe again. This system is common in homes in the USA and in continental Europe. Recently this flush system has also become available in the UK due to a change in regulations.

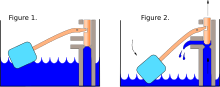

Tank style with siphon-flush valve[edit]

This system, invented by Albert Giblin and common in the UK, uses a storage tank similar to that used in the flapper-flush-valve system above. This flush valve system is sometimes referred to as a valveless system, since no traditional type of valve is required. Some would argue, however, that any system of regulating the flow of a fluid is still technically a valve. In the siphon-flush-valve system, the user pushes a lever or button, forcing the water up into the tank siphon passageway which then empties the water in the tank into the bowl. The advantage of a siphon over the flush valve is that it has no sealing washers that can wear out and cause leaks, so it is favoured in places where there is a need to conserve water. Until recently, the use of siphon-type cisterns was mandatory in the UK to avoid the potential waste of water by millions of leaking toilets with flapper valves but due to EU harmonisation the regulations have changed. These valves can sometimes be more difficult to operate than a "flapper"-based flush valve because the lever requires more torque than a flapper-flush-valve system. This additional torque required at the tank lever is due to the fact that a user must forcefully lift a certain amount of water up into the siphon passageway in order to initiate the siphon action in the tank.

Older installations, known as "high suite combinations", used a high-level cistern (tank), fitted above head height, that was operated by pulling a chain hanging down from a lever attached to the cistern. When more modern close-coupled cistern and bowl combinations were first introduced, these were first referred to as "low suite combinations". Modern versions have a neater-looking low-level cistern with a lever that the user can reach directly, or a close-coupled cistern that is even lower down and integrated with the bowl. In recent decades the close coupled tank/bowl combination has become the most popular residential system, as it has been found by ceramic engineers that improved waterway design is a more effective way to enhance the bowl's flushing action than high tank mounting.

It can now be found in dual flush versions.

Tank style with high-pressure or pressure-assist valve[edit]

This system utilizes water main pressure to pre-pressurize a plastic tank located inside what otherwise appears to be the more typical ceramic flush tank. A flush cycle begins each time a user flushes the bowl. After a user flushes and the water in the pre-pressurized tank has finished emptying into the bowl, the outlet valve in the plastic tank shuts. Then the high pressure water from the main refills the plastic tank. Inside the tank is an air-filled balloon-like rubber diaphragm. As the higher-pressure mains water enters the tank, the rubber diaphragm is also pressurized and shrinks accordingly. During flushing, the compressed air inside the diaphragm pushes the water into the bowl at a flow rate which is significantly higher than a tank style gravity-flow toilet. This system requires slightly less water than a gravity-flow toilet- or alternatively can be more effective for a similar amount of water. Pressure-assist toilets are sometimes found in both private (single, multiple and lodging) bathrooms as well as light commercial installations (such as offices). They seldom clog, but the pressurized tanks require replacement about once every 10 years. They also tend to be noisier - a concern for residential settings. The inner bowl stays cleaner (in appearance) than gravity counterparts because of the larger water surface area and the toilet's forceful flush. Newer toilets from several companies such as Kohler that are pressure-assisted use 1.4 US gallons (5.3 l) to 1.1 US gallons (4.2 l) per flush.

Tankless style with high-pressure (flushometer) valve[edit]

In 1906, William Sloan first made his "flushometer" style toilet flush valve, incorporating his patented design,[15] available to the public. The design proved to be very popular and efficient, and remains so to this day. Flushometer toilet flush valves are still often installed in commercial restrooms, and are frequently used for both toilets and urinals. Since they have no tank, they have zero recharge time, and can be used immediately by the next user of the toilet. They can be easily identified by their distinctive chrome pipe-work, and by the absence of a toilet tank or cistern, wherever they are employed.

Some flushometer models require the user to either depress a lever or press a button, which in turn opens a flush valve allowing mains-pressure water to flow directly into the toilet bowl or urinal. Other flushometer models are electronically triggered, using an infrared sensor to initiate the flushing process. Typically, on electronically triggered models, an override button is provided in case the user wishes to manually trigger flushing earlier. Some electronically triggered models also incorporate a true mechanical manual override which can be used in the event of the failure of the electronic system. In retrofit installations, a self-contained battery-powered or hard-wired unit can be added to an existing manual flushometer to flush automatically when a user departs.

Once a flushometer valve has been flushed, and after a preset interval, the flushometer mechanism closes the valve and stops the flow. The flushometer system requires no storage tank, but requires a high volume of water in a very short time. Thus a 3/4 inch (19 mm) pipe at minimum, or preferably a 1 inch (25 mm) pipe, must be used, but as the high volume is used only for a short duration, very little water is used for the amount of flushing efficacy delivered. Water main pressures must be above 30 pounds per square inch (2.1 bar). While the higher water pressure employed by a flushometer valve does scour the bowl more efficiently than a gravity-driven system, and while fewer blockages typically occur as a result of this higher water pressure, flushometer systems still require approximately the same amount of water as a gravity system to operate (1.6 gpf).

Bowl design[edit]

The bowl, loo or pan, of a toilet is the receptacle that receives bodily waste. A toilet bowl is most often made of a ceramic, but can sometimes be made of stainless steel or composite plastics. Toilet bowls are mounted in any one of three basic manners: above-floor mounted (pedestal), wall mounted (cantilever), or in-floor mounted (natural position).

Within the bowl, there are three main water-way design systems: the siphoning trapped system (found primarily in North American residential installations, and in North American light commercial installations), the non-siphoning trapped system (found in most other installations both inside and outside of North America), and the valve-closet system (found in many specialty applications, such as in trains, planes, buses, and other such installations around the world). Older style toilets called "washout" toilets are now only found in a few locations.

Siphoning-toilet[edit]

The siphoning-toilet is perhaps the most popular design in North America for residential and light commercial toilet installations. Some other terms for these types of toilets are "siphon jet", "siphon wash", and in North America, "wash down". All siphoning-toilets incorporate an 'S' shaped water-way. The water-ways in these toilets are designed with slightly smaller diameters than a non-siphoning toilet, so that the water-way will naturally fill up with water, each time it is flushed, thus creating the siphon action. To flush the toilet the user activates a flushing mechanism (see above), which pours a large quantity of water quickly into the bowl. This creates a flow large enough to purge the bowl's water-way of all air, thus causing the bowl to empty rapidly due to the siphon action that has been created. This flow stops as soon as the water level in the bowl drops below the first bend of the siphon, allowing air to enter the S-pipe to break the column of liquid and to halt the siphonic action.

A "true siphoning-toilet" can be easily identified by the noise it makes. If it can be heard to suck air down the drain at the end of a flush, then it is a true siphoning toilet. If not, then it is either a double trap siphonic or a non-siphoning toilet.

Double trap siphonic toilet[edit]

The double trap siphonic toilet is a less common type that is exceptionally quiet when flushed. There is a device known as an aspirator which uses the flow of water on a flush to suck air from the cavity between the two traps, reducing the air pressure there to create the siphon which sucks water and waste from the toilet bowl. Towards the end of the flush the aspirator ceases being covered in water, thus allowing air into the cavity between traps to break the siphon without the noise while the final flush water fills the pan.[16][17][18]

Non-siphoning toilet[edit]

Valve closet[edit]

The valve closet has a valve or flap at the exit of the bowl with a water-tight seal to retain a pool of water in the pan. When the toilet is flushed, the valve is opened and the water in the pan flows rapidly out of the bowl into the drains, carrying the waste with it.

The earliest type of toilet, the valve closet is now scarce as a water-flush toilet. More complicated in design than other water closets, reliability is lower and maintenance more difficult. The most common use for valve closets is now in portable closets for caravans, camping, trains, and aircraft where the flushing fluid is recycled. This design is also used in train carriages in areas where the waste is allowed to be simply dumped between the tracks (the flushing of such toilets is generally prohibited when the train is in a station).

Washout toilet[edit]

Further information: Washout toilet

Washout toilets have a shallow pool of water into which waste is deposited, with a trapped drain just behind this pool. Waste is cleared out from this pool of water by being swept over into the trap (usually either a P-trap or an S-trap) and then beyond into a sewer by water from the flush. Washout pans were amongst the first types of ceramic toilets invented and since the early 1970s are now only found in a decreasing number of localities in continental Europe.

Reverse bowl design (Flachspüler)[edit]

In the Netherlands, Germany, Austria and some regions of Poland, the bowl is designed to hold the fecal matter out of the water prior to flushing by means of a receiver shelf, whereas most U.S. or U.K. designs immediately allow it to plunge into standing water. This reverse design prevents the occurrence of any splash-up which commonly happens when fecal matter plunges into the standing water in the standard designs (although substantial deposits may cause splash-up problems of their own). The disadvantage is that it also increases the associated odor and may require the use of a brush to remove bits of feces that may have "skid-marked" on the shelf. Similar designs are found in some early toilets in the U.S., one particular brand being labeled the "Grand Niagara", as the flushing of the shelf creates a waterfall effect into the drain chamber.

Cultural variations[edit]

In India, the "Anglo-Indian" design allows the same toilet to be used in the sitting or the squatting position. This type of toilet is also used on most Russian older style trains, made in Eastern Germany (Ammendorf factory, design dated probably to the 50s), employing a pan-like shutter valve discharging waste directly on the railway. The toilet usage is permitted only on the go, and outside of major cities. These toilets are currently vanishing, together with the old trains, being replaced with modern vacuum systems.

For a review of Japanese toilet usage and history, see Toilets in Japan.

Low-flow and high-efficiency toilets[edit]

Main article: Low flush toilet

Since 1994, there is a significant move towards using less water for flushing flush toilets. This has resulted in the emergence of low flush toilet designs and national standards on water consumption for flushing. In addition, some people modify their existing high flush toilet to use less water by placing a brick or water bottle into the toilet's water tank.[19] Other modifications are often done on the water system itself, e.g. by using greywater, or a system that pollutes the water more gradually; hence more efficient use of the water is accomplished.

US Standards for new toilets[edit]

Pre-1994 residential and pre-1997 commercial flush toilets use 3.4 US gallons (13 L) of water per flush (gpf or lpf). In 1992, the United States Congress passed the Energy Policy Act of 1992, which mandated that beginning in 1994 common flush toilets use only 1.6 US gallons (6.1 L).[20] In response to the Act, manufacturers produced low-flow toilets, which many consumers did not like because they often required more than one flush to remove solids. People unhappy with the reduced performance of the low-flow toilets resorted to driving across the border to Canada or Mexico, or buying salvaged toilets from older buildings.[21] Manufacturers responded to consumers' complaints by improving the toilets. The improved products are generally identified as high efficiency toilets or HETs. HETs possess an effective flush volume of 1.3 US gallons (4.9 L) or less.[22] HETs may be single-flush or dual-flush. A dual-flush toilet permits its user to choose between two amounts of water.[23] Some HETs are pressure-assisted (or power-assisted or pump-assisted or vacuum-assisted).

The performance of a flush-toilet may be rated by a Maximum Performance (MaP) score. The low end of MaP scores is 250 (250 grams of simulated fecal matter). The high end of MaP scores is 1000. A toilet with a MaP score of 1000 should provide trouble-free service. It should remove all waste with a single flush; it should not plug; it should not harbor any odor; it should be easy to keep clean. The United States Environmental Protection Agency uses a MaP score of 350 as the minimum performance threshold for HETs.[22] 1.6 gpf toilets are also sometimes referred as ULF (Ultra Low Flow) toilets.

Methods used to make up for the inadequacies of low flow toilets include using thinner toilet paper,[24] plungers, and adding extra cups of water to the bowl manually.[25]

Miscellaneous[edit]

Swirl direction[edit]

It is a commonly held misconception that when flushed, the water in a toilet bowl swirls one way if the toilet is north of the equator and the other way if south of the equator, due to the Coriolis effect – usually, counter clockwise in the northern hemisphere, and clockwise in the southern hemisphere. In reality, the direction that the water takes is much more determined by the direction that the bowl's rim jets are pointed, and it can be made to flush in either direction in either hemisphere by simply redirecting the rim jets during manufacture. On the scale of bathtubs and toilets, the Coriolis effect is too weak to be observed except under laboratory conditions.[26]

Toilet cleaning[edit]

Ordinary toilet cleaning is done by a toilet brush.

Toilet clogging[edit]

Clogging usually occurs as a result of an attempt to flush unsuitable items, or too much toilet paper. Flushing hair should also be avoided. However, clogging can occur spontaneously due tolimescale fouling of the drain pipe or by overloading the stool capacity of the toilet. Stool capacity varies among toilet designs and is based on the size of the drainage pipe, the capacity of the water tank, the velocity of a flush and the method by which the water attempts to vacate the bowl of its contents. The size and consistency of the stool is also a contributing, but hard to predict factor. In recent years clogging has become more frequent due to regulations that require the use of small tanked low-flush toilets in attempt to conserve water. Sometimes, three to four flushes periodically during the use of a low-flush toilet may be required to prevent clogging, thus conserving less water than larger tanked toilets. Clogging is particularly insidious, as it is usually not discovered immediately, but only later by an unsuspecting user trying to flush a loaded toilet. Overflowing of the water mixed with excrement may then occur, depending on the bowl volume, tank capacity and severity of clogging. For this reason, rooms with flush toilets should be designed as wet rooms, with a second drain on the floor, and a shower head capable of reaching whole floor area. Common means to remedy clogging include use of toilet plunger, drain cleaner or a plumber's snake.

Fire safety in multi-story buildings[edit]

Main article: Firestop

| This section does not cite any references or sources. (September 2011) |

Toilets in multi-story buildings, located on fire-resistance rated floors typically require at least two through-penetrations, which can compromise the rating of the floor if left untreated. One opening is for the fresh water supply to flush and/or fill the water tank. The other through-penetration is for the drain pipe. The fresh water supply line requires routine firestopping. The drain pipe, however, is exempt from firestopping in many building codes, particularly when noncombustible piping is used, because the penetration terminates on the unexposed side in a ceramic bowl filled with water, which can withstand significant fires. Intumescent firestops are often used, in the event plastic pipes are used for toilet drains, so that the melting plastic pipe is choked off in the event of an accidental fire. It is, however, customary to fill the metallic drain pipe annulus with rockwool packing. Even with the best of intentions, it would be difficult for the firestopper to install a sealant, because he is not allowed or inclined to remove the flange, which is what is partially used to support the drain pipe below during the installation process.

No comments:

Post a Comment

Jayant Parkash Is Welcome All world to my blog